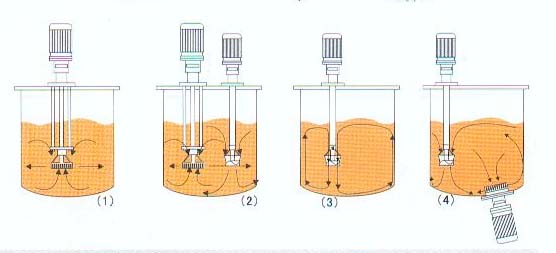

Operation Principle

High shear dispersing emulsifier effectively,quickly and evenly disperse a phase or phases to another consecutive phase,usually,these phases ar© dissolvable to each other.The rotor revolves quickly and strong fore© is produced through high tangent speed and high frequency mechanical effect,therefor©,th© material in th© narrow slotamong stator and rotor receives strong forces from mechanical and liquid shearing,centrifugal forc©,pre^ing,liquid fraction,clashing,tearing and rush water.The dissolvable solid,liquid and gas material is then instantly dispersed and emulsified evenly and finely with b©l©r production procedures and appropriate addictives and finally products with stable high quality are made.

Intermittent High Shear Dispersing

Emulsifier Working Process

Th© rotor revolves in high speed produces centrifugal force,which suctions the material from upper and lower feeding area axially to the operation chamber.

The strong centrifugal force throws the material axially tc th© narrow slot between stator and rotor.The material then receives centrifugal press,clash and other forces,which firstly disperse and emulsify the material.

Th© outer terminal of th© rotor revolved in high speed produces a lin© speed mor。than 15m/s and even up to 40m/s,which produces strong mechanical and liquid shearing,liquid abrasion,clashing and tearing which fully disperse,emulsify,homogonrand break the material and jet from th© stator slot.

As materials jet in radial in high speed,they change their flow direction with resistance from themselves and vessel walls.The upperand lower axial suction force then leads to strong upper and lower rushing flows.After many circulations,the material is finally disper sed and emulsified ovonly.

|

Type |

KW |

RPM |

Capacity(L) |

Weight(KG) |

|

JR-90 |

1.5 |

2900 |

5-50 |

60 |

|

JR-100 |

2.2 |

2900 |

50-100 |

60 |

|

JR-120 |

4 |

2900 |

100-300 |

80 |

|

JR-140 |

7.5 |

2900 |

200-800 |

|

|

JR-160 |

11 |

2900 |

300-1000 |

220 |

|

JR-180 |

18.5 |

2900 |

500-1500 |

|

|

JR-200 |

22 |

1450 |

800-2000 |

|

|

JR-220 |

30 |

1450 |

1000-3000 |

|

|

JR-240 |

37 |

1450 |

1500-5000 |

|

|

JR-270 |

55 |

1450 |

2000-8000 |

|

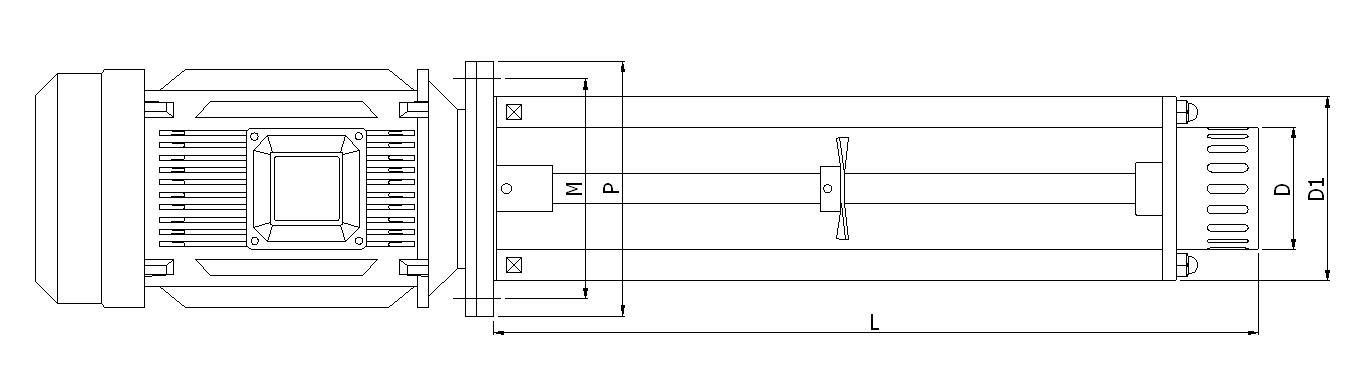

T |

D |

D1 |

P |

L |

M |

|

|

JR-90 |

80 |

140 |

200 |

355 |

165 |

|

|

JR-100 |

88 |

145 |

200 |

650 |

165 |

|

|

JR-120 |

120 |

180 |

250 |

750 |

215 |

|

|

JR-130 |

130 |

190 |

250 |

900 |

230 |

|

|

JR-140 |

140 |

210 |

300 |

900 |

265 |

|

|

JR-160 |

160 |

230 |

350 |

1050 |

300 |

|

|

JR-180 |

180 |

260 |

350 |

1200 |

300 |

|

|

JR-200 |

200 |

270 |

350 |

1200 |

300 |

|

|

JR-220 |

240 |

320 |

400 |

1355 |

350 |

|

|

JR-240 |

260 |

340 |

400 |

1395 |

350 |