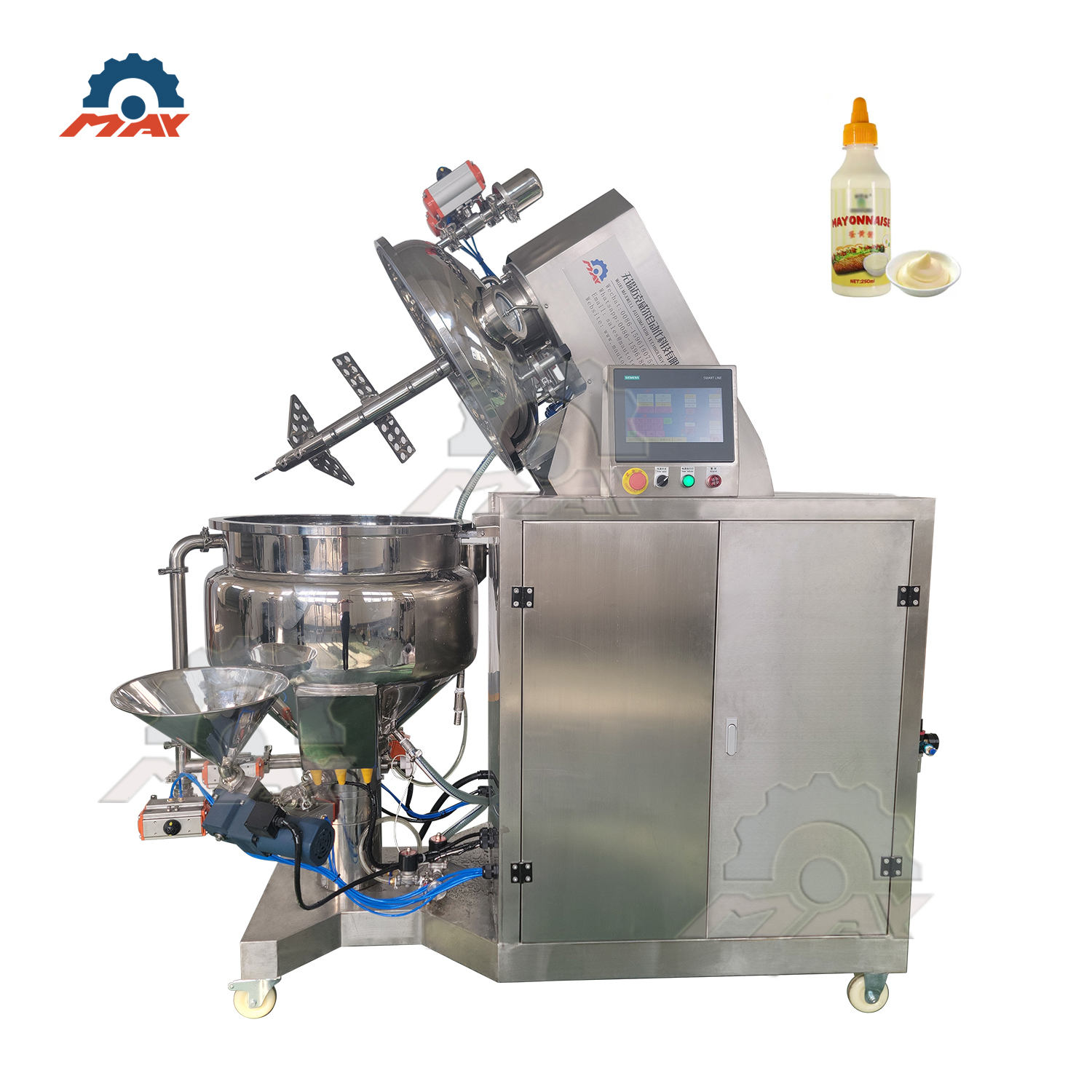

Gynecological Gel Syringe Filling Machine

- Price RMB80000

- Type MAX-30

- Click E-mail to :sales@mautotech.com

Overview :

MAX-30 gel filling machine is mainly used for the principle of single transmission. A series of functions such as automatic filling, capping, capping and finished product withdrawal are completed by using the splitter to drive the rotary plate equipped with fixture for intermittent movement. Filling measurement is accurate, the speed is adjustable. The machine is set up for 10 slots, in addition to manual pipe, other can be completed automatically. The whole machine runs smoothly and reliably, without noise and other pollution.

All the contact materials and some related parts of the machine are made of high-quality stainless steel, and the parts that need to be cleaned are selected quick change devices, which is convenient for disassembly and washing. Where some materials need heating insulation, the external barrel can be equipped with heating constant temperature device.

The whole machine transmission principle :

The machine by a motor as the main power, through the worm gear reducer and frequency conversion speed regulation, through the splitter, gear for intermittent operation, so that installed on the turntable 10 jig for equal Angle movement. After manual tube, material filling can be carried out, the whole filling system is driven by cylinder, and is equipped with metering adjustment screw, which can be measured and adjusted within a certain range, the accuracy can reach ± 1%. In order to avoid the external drip of the material, the filling nozzle of the machine is inserted, and the advance and advance work is also completed by the lifting cylinder.

All the pipes that have been filled are covered and capped at the same time when they are introduced to the next station, so the machine rotates a station and completes a product at the same time, and the maximum production capacity can reach 40 pieces in one minute.

All filling is controlled by splitter and solenoid valve to complete the required action, the whole working condition runs smoothly, reliable, repeatable performance is good, the movement to the position rate can reach 100%, without mistakes, safe and reliable, easy to operate. After use by all users are very satisfied, generally good response.

Parameter:

1.Power supply: ~220V±10%

2.Power consumption :1.5kw

3.Air source(Mpa):air pressure > 0.6Mpa

4.Filling capacity(ml): 3-30(ml), Also can customized as per customer demand

5.Speed: 25-40 pcs/min

6.Measure precision: ±1%

7.Dimension(mm): 1130*810*1600(net)

After packed: 1060*830*1600mm

8.Weight of the machine (kg):300㎏