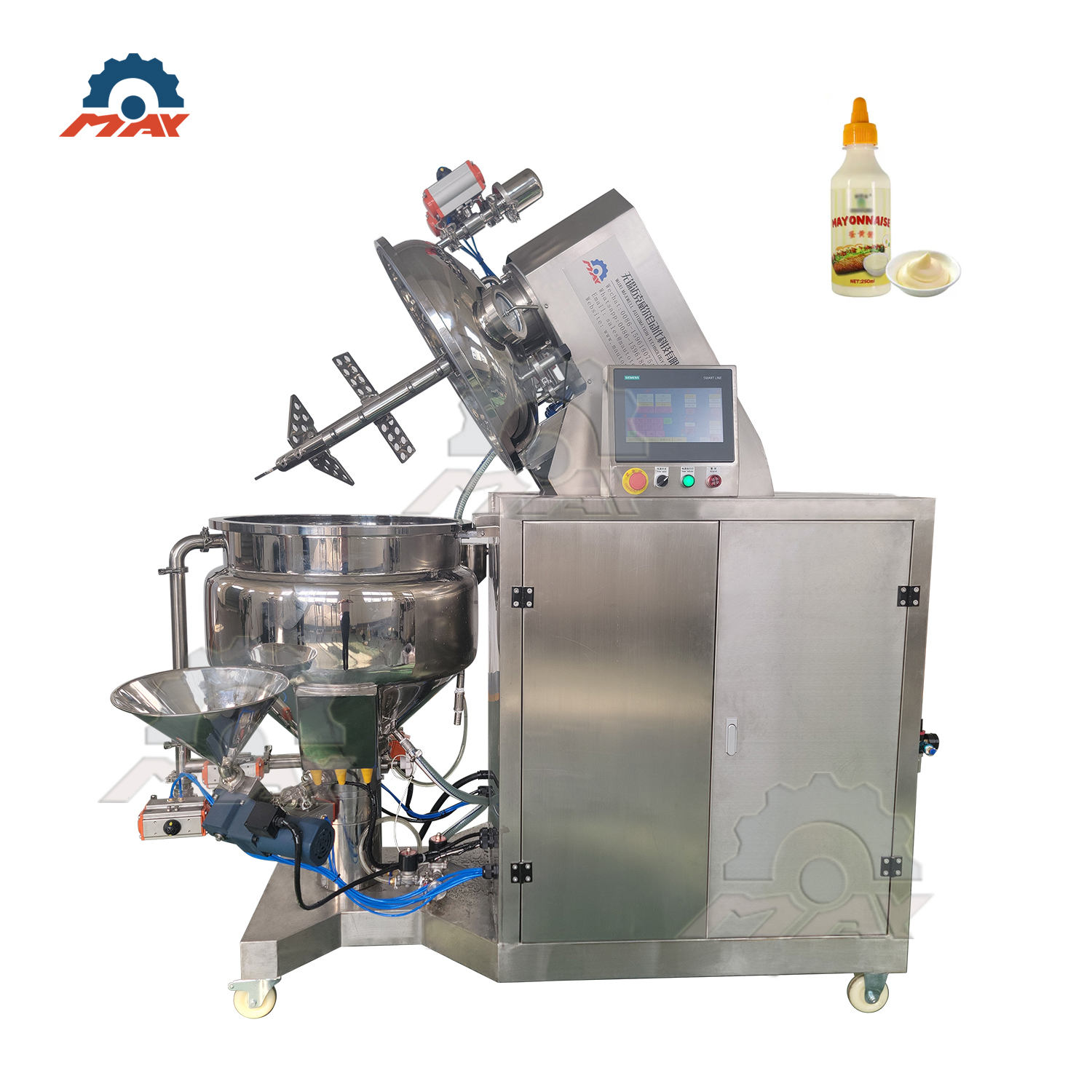

Vacuum Emulsifying Mixer (industry grade)

- Price

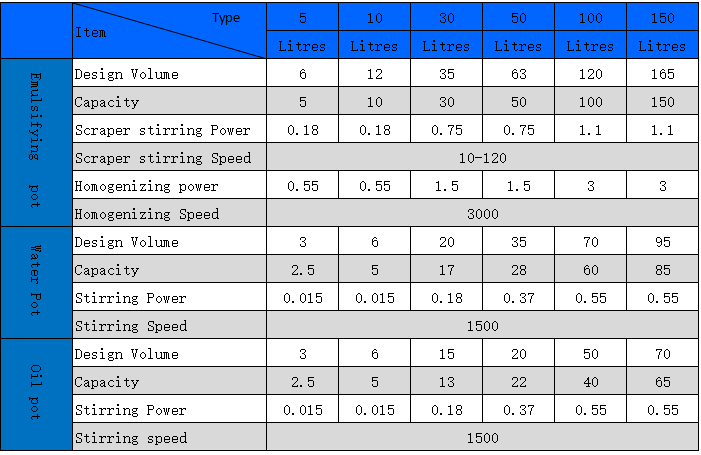

- Type 30L50L price below

- Click E-mail to :sales@mautotech.com

30L vacuum main pot USD9000 Optional : oil phase and water phase pot USD2000

50L vacuum main pot USD10000 Optional : oil phase and water phase pot USD3000

Working Process:

Vacuum Emulsifying Mixer

Vacuum Emulsifying Mixer

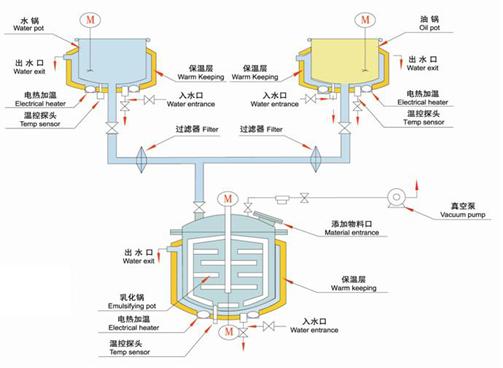

Put the materials into premix tank oil phase tank and water phase tank,after heated & mixed in water tank and oil tank, it can drawn the materials into emulsifying tank by vacuum pump. Adopting the middle stirrer & Teflon scrapers residues in emulsifying tank that sweep the residues on the wall of the tank to makes the materials wiped off become the new interface constantly. Then the materials will cut off, compressed and fold by the blades to stir, mix and run to the homogenizer. By the strong cutting off, impact and turbulent current from the high-speed shear wheel and fixed cutting case, the materials are cut off in interstices of stator and rotor and turn to particles of 6nm-2um promptly. Because the emulsifying tank is working under the vacuum state, the bubbles that produces in the process of mixing is taken away in time.

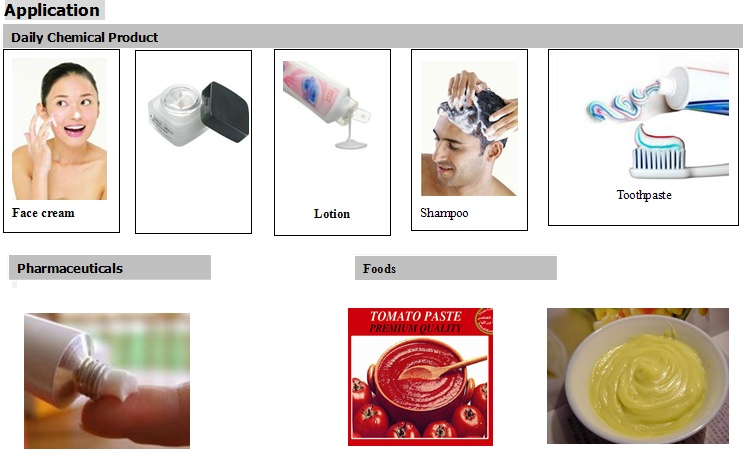

vacuum emulsifying mixer is widely use for below products:

- Cosmetic: face cream, hand cream, sunscreen cream, eyelash to cream, hair gel, lotion, bath shampoo, nail polish, hair conditioner etc.

- Pharmaceutical industry: ointments, syrup, nutrition, bio-products, paste of pharmaceutical etc.

- Daily use industry: toothpaste, detergents, shoes polish, soap, fragrance etc.

- Food industry: sauces, jam, chocolate, butter, vegetable proteins, animal proteins etc.

- Chemical industry: Painting, pigment, dyes, paints, adhesives detergents etc.

FAQ